In the sewage industry, wastewater treatment is a big job. It’s not something often discussed in everyday conversations within our local communities. But, with more attention being focused on sustainability and the future of our environment, things are changing. Today, there is more interest in – and more talk about – water treatment processes, overall.

In the sewage industry, wastewater treatment is a big job. It’s not something often discussed in everyday conversations within our local communities. But, with more attention being focused on sustainability and the future of our environment, things are changing. Today, there is more interest in – and more talk about – water treatment processes, overall.

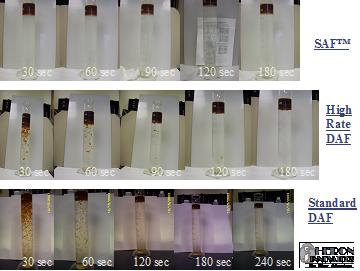

In the sewage industry, especially, there is growing concern about what’s being done to clean up the water. Currently, popular processes for removing suspended solids from wastewater include SAF™ (Suspended Air® Flotation) and DAF (dissolved air flotation); SAF being the newer innovation of the two types of processes. The SAF process uses an externally generated bubble suspension containing very high air content, key to a flotation process capable of 10 times the hydraulic loading and 10 times the solids loading rate of DAF. So, it’s easy to see why, within the past few decades, SAF has replaced DAF as the method of choice for removal of suspended solids from wastewater.

Here’s how it works: The SAF process encapsulates each air bubble with a chemically active film that strongly attaches to flocculated solids in the wastewater, achieving high loading rates and more efficient flotation. Comparatively, the DAF process uses high pressure, a very high recirculation rate and is dependent on physical entrapment and weak surface bonds to achieve its results.

At the heart of the SAF process is the SAF Froth Generator responsible for the superior effectiveness and efficiency of the system. Standard features of the SAF Froth Generator are:

- A sealed generator module

- Frothing agent metering pump

- Instrumentation, sensors and controls, and

- Recycle pump.

The SAF process makes evaluating treatability a much simpler task. By employing the laboratory scaled generator an investigator can easily assess chemical conditioning recipe and flotation. The process utilizing the SAF bench generator is far simpler than testing that incorporates a bench style DAF apparatus. In addition, results are immediately applicable and reliably scale to full production operations. It’s important to also remember what we previously said: The SAF Froth Generator operates a flotation process at 10 times the hydraulic loading and 10 times the solids loading rate of DAF.

SAF jar testing can be reliably scaled and performed on site/in the field, due to the smaller scale of the SAF process. Results are immediately applicable to the entire water treatment operations – and that’s big news for the wastewater treatment industry.